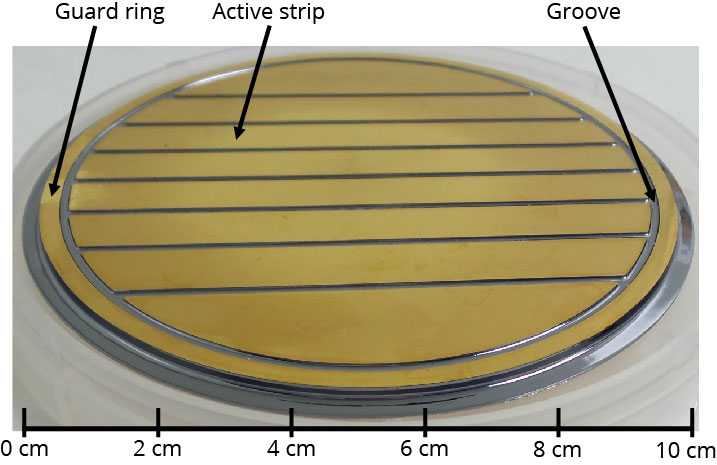

A typical GAPS flight detector showing the guard ring and active strips.

A typical GAPS flight detector showing the guard ring and active strips.

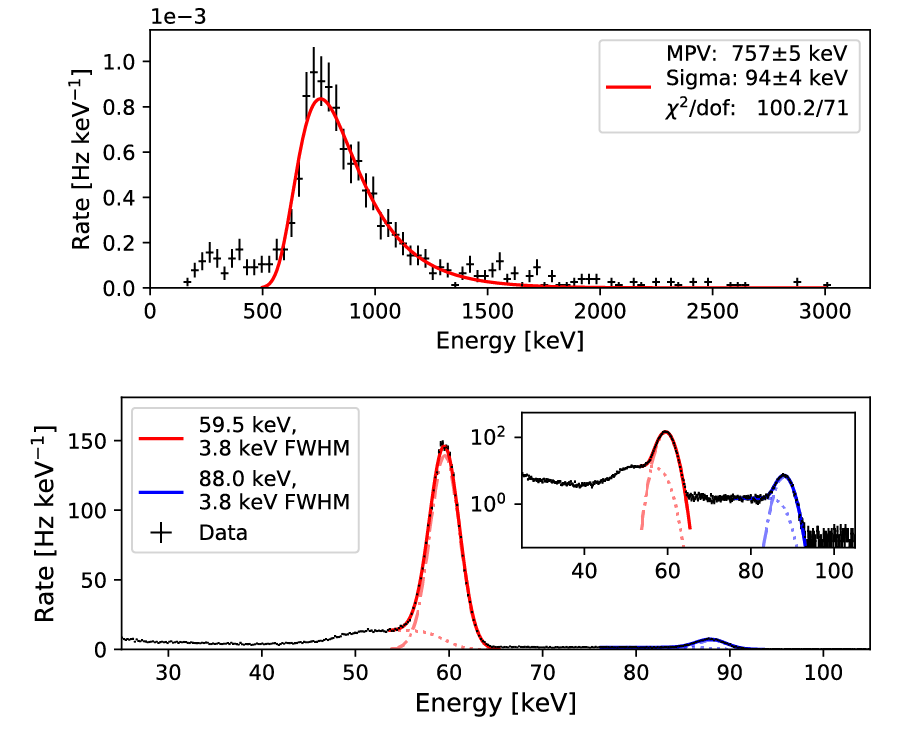

The Si(Li) detector performance was evaluated using γ-rays from radioactive sources as well as cosmic muons. Energy resolution in the X-ray range was evaluated using two mono-energetic lines, 59.5 keV from 241Am and 88.0 keV from 109Cd. Resolution of < 4 keV was achieved at a temperature of -35°C (top). We verified tracking capability using cosmic muons (bottom), observing the expected energy distribution for minimum ionizing particles traversing 2.3 mm of silicon, with uncertainty < 10%.

The Si(Li) detector performance was evaluated using γ-rays from radioactive sources as well as cosmic muons. Energy resolution in the X-ray range was evaluated using two mono-energetic lines, 59.5 keV from 241Am and 88.0 keV from 109Cd. Resolution of < 4 keV was achieved at a temperature of -35°C (top). We verified tracking capability using cosmic muons (bottom), observing the expected energy distribution for minimum ionizing particles traversing 2.3 mm of silicon, with uncertainty < 10%.

More than 1000 lithium-drifted silicon, or Si(Li), detectors, form the heart of the GAPS Tracker. These detectors serve as the target, slowing down the antinucleus cosmic-ray particles of interest to GAPS and capturing the antinuclei into exotic atoms, and as the sensors that detect the X-rays and hadronic particles from exotic atom decay and annihilation. Si(Li) detectors have been developed since the 1960s, but previous models had to be operated at liquid nitrogen temperatures (not accessible on a large balloon experiment), were not sensitive to X-rays, or were too small (or expensive) to feasibly instrument a large volume. Therefore, we worked with Shimadzu Corporation to develop a scalable production method for large-area Si(Li) detectors (read more) that can be used for X-ray detection at temperatures as warm as -40°C, achievable by the GAPS thermal system. These detectors have energy resolution < 4 keV (FWHM) in the 20-100 keV range, as required for identification of characteristic exotic atom X-rays, and energy resolution better than 10% in the range up to 100 MeV, as required for dE/dx identification of different incoming antinuclei species and tracking capability for outgoing annihilation products.

The GAPS Si(Li) detectors (see Figure 1) are made from 10 cm diameter, 2.5 mm thick wafers of boron-doped silicon. The detectors are fabricated (read more) by evaporating lithium onto the top surface of a wafer and thermally diffusing it to a depth of ~0.1 mm, forming an n+-layer. The lithium ions are then drifted through the bulk of the material by applying a 600V bias for ~100 hrs, producing a thick (~2.3 mm) layer of compensated silicon and leaving a thin (~0.1 mm) undrifted p-type layer. The electrodes are nickel and gold evaporated on the surfaces. The guard ring structure and 8 parallel strips within the guard ring are defined by machining 0.3 mm-deep grooves into the wafer. When the detector is operated under reverse bias, the compensated volume is depleted of free electrons and holes, such that the grooves isolate the strips electrically from each other and the guard ring. The guard ring, which is grounded during operation while signal is read out from the 8 active strips, is critical for high-temperature energy resolution performance. It isolates the leakage current that flows along the outside surface of the wafer, which can be many orders of magnitude larger than the bulk leakage current, from the active area. A custom polyimide-based passivation scheme has also been developed, in order to protect the detectors from environmental effects that could increase leakage current.

The resulting performance is summarized in Figure 2 (read more). The detectors achieve the required X-ray resolution while operating at ambient flight pressures and the relatively-high temperatures of -35 to -55°C. The energy deposition from ionizing particles is also reconstructed to well within the required 10% accuracy. These will be the first such large-area, high-temperature spectroscopic Si(Li) detectors to be operated in a space mission. The detectors, while developed specifically for GAPS, may have other applications, e.g. in heavy nuclei identification at rare isotope facilities.